Explaining Bandsaw Blade Performance

21 November 2022

In our previous video blog, we defined blade life and discussed the importance of knowing your blade’s cost per cut. However, while blade life is an extremely important factor to consider when purchasing a blade, it’s not the only one you should consider. Usually, pricing is the first thing blade users care about. In other

- Published in Blade Tips

No Comments

Explaining Blade Life & Cost Per Cut

03 November 2022

If you purchase blades from a manufacturer like Simmons or a bandsaw OEM, you’ve probably heard the term “blade life” at least a dozen times before. Put simply, blade life can be equated to the amount of work completed by a blade before it loses its effectiveness. While it’s typically determined on a case-by-case basis,

- Published in Blade Tips

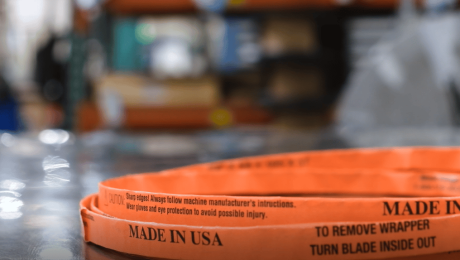

How to Quickly Uncoil & Unwrap Butcher Blades

21 September 2022

If you’re not someone who handles butcher blades on a daily basis, uncoiling and unwrapping them can become a bit of a hassle. Since Simmons strives to eliminate our customers’ hassles wherever possible, we decided to put together this video on how to quickly uncoil and unwrap your butcher blades. Press the play button below

- Published in Blade Tips

Grinding Wheel Best Practices – How to Perform a Ring Test

24 August 2022

If you’re working with bandknife or bandsaw blades, chances are you’ll eventually need to use a grinding wheel. However, before you mount a new grinding wheel, you should always perform a ring test to make sure it is in fully intact. We know you probably wish you could just start grinding away but performing a

- Published in Blade Tips

Does your business cut bone-in or boneless meats using food processing machinery from OEMs like Butcher Boy, Grasselli, Grote, or Hobart? Or are you fabricating foam sheets using peeling and splitting machines from OEMs like Baumer, Edge-Sweets, or Fecken-Kirfel? If so, it’s likely tempting to simply order replacement blades for those machines from the same

- Published in Blade Tips

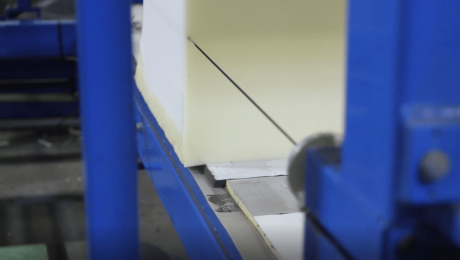

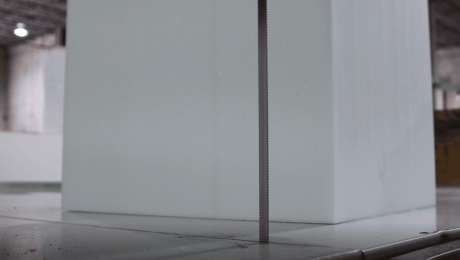

4 Common Foam Types & How to Cut Them

21 June 2022

Simmons has manufactured bandknife and bandsaw blades for foam cutting operations for more than 75 years. In that time, we’ve learned about all different types of foam and, more importantly, which blade or edge type cuts them best for their intended purpose. Now, we’d like to share what we’ve learned with you. Flexible Polyurethane Foam

- Published in Blade Tips

The Importance of Blade Tension

22 April 2022

While it may not seem important at first, the extent to which you tension your bandknife or bandsaw blades can literally make or break your finished product. That’s why it’s imperative to properly apply blade tension before you run it on a bandsaw and look out for signs of under or over tensioning while it’s

- Published in Blade Tips

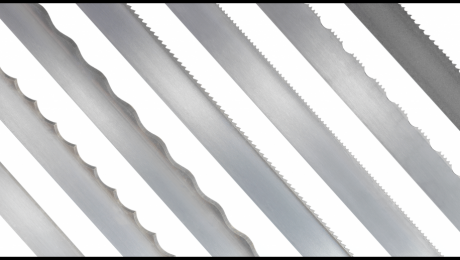

Choosing the Right Bandsaw Blade

02 March 2022

Imagine finding the perfect bandsaw blade. One that’s capable of cutting through all types of material at a faster rate than any other blade on the market. Sounds nice, right? Unfortunately for everyone, it doesn’t exist…yet. So, until our engineers design this blade (we’re sure it’s only a matter of time), the best we can

- Published in Blade Tips

Identifying Causes of Blade Failure

09 December 2021

In our previous blog post, we covered the definition of blade life and how to determine it over time. Naturally, it makes sense to next discuss what happens when bandsaw blades reach the end of their lives. There are two different categories of blade failure: normal and premature blade failure. Let’s dive into each one

- Published in Blade Tips