NARROW KNIFE EDGE BLADES

Known for its versatility, Simmons’ Narrow Knife Edge blade is designed to slice and peel a variety of soft products. Its finely sharpened edge results in a consistently smooth finish every time for every application. The carbon steel blade (also available in stainless steel) will also retain its edge for longer when used with grinding wheels specifically matched to the steel type and slicing application.

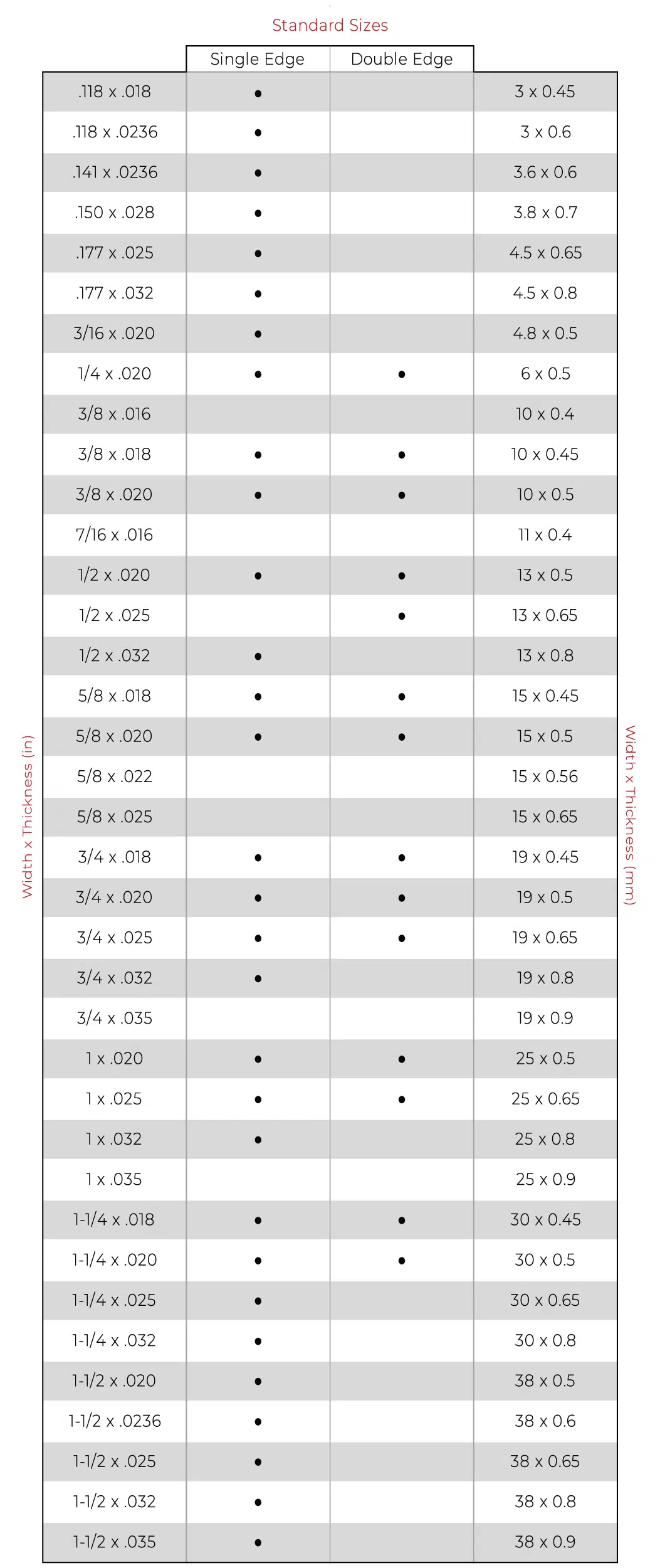

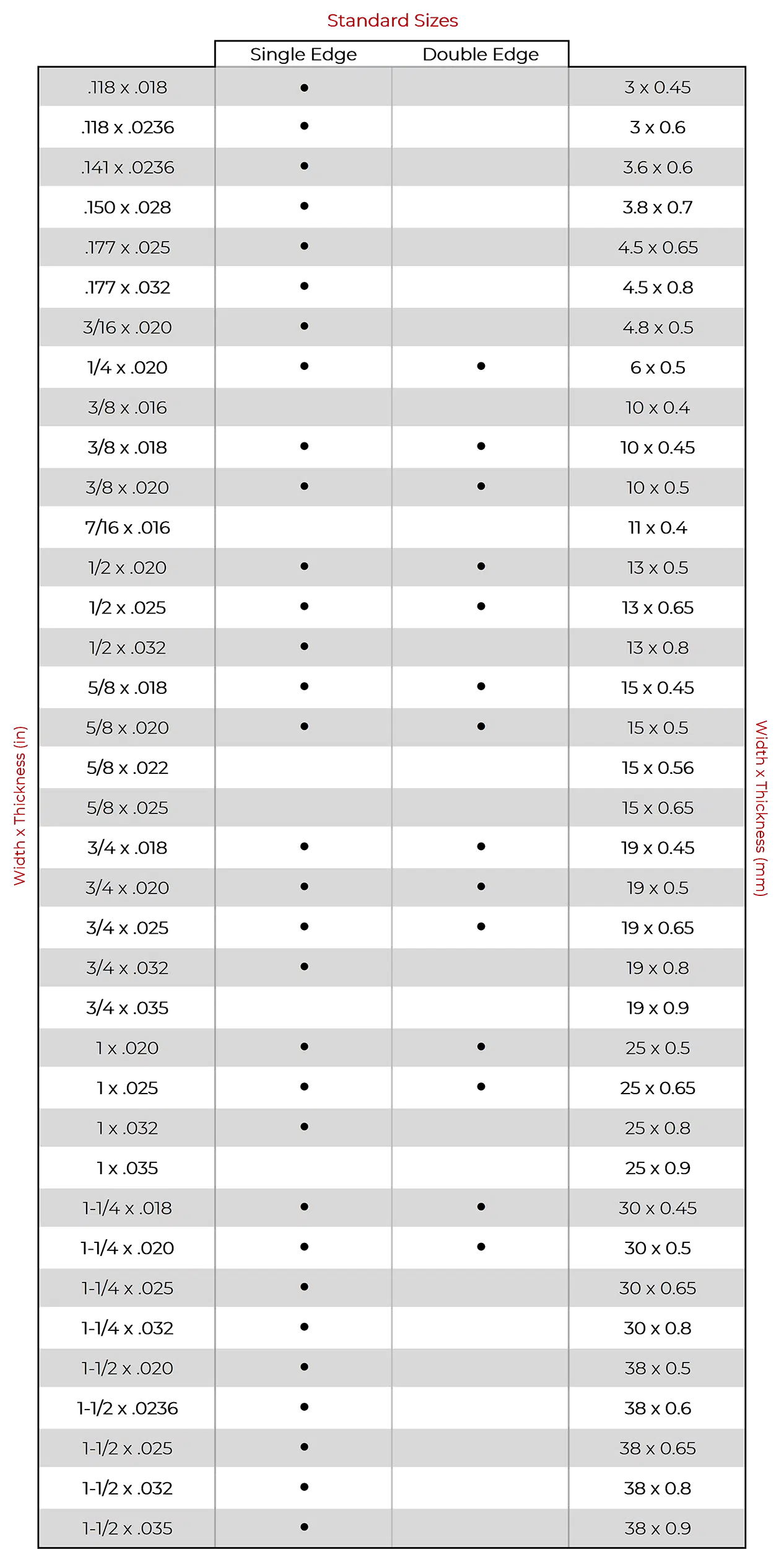

Narrow Knife Edge blades are available in both band and cut-to-length form. We also offer custom hole and rivet configurations for boneless meat, cheese, and produce slicing and dicing reciprocating applications.

Recommended cutting applications for Narrow Knife Edge blades:

- Low-density foam

- Rubber

- Packaging materials

- Fabric

- Insulation material

- Vegetables

- Cheese

- Boneless meat products

- Tissue paper

Consistently delivering high-quality blades has been key to Simmons’ success throughout the years. As part of our reliable welds guarantee, if a Simmons blade breaks at the weld, just let us know and we’ll replace that blade for you.

We stand behind our workmanship, and even when we’re not at fault for blade issues, we frequently invest in analyzing the cause of the blade’s failure in order to educate our customers and help them correct the source of the issue in their facility.

Double Edge Single Bevel (KSSB)

Single Edge Single Bevel (KSB)

Double Edge Double Bevel (KDDB)

Single Edge Double Bevel (KDB)

As part of our Narrow Knife Edge blade production process, Simmons offers an additional option to harden the cutting edge of the blade in order to extend overall blade life.

*Does not apply to double edge blades.*