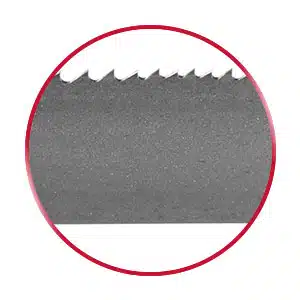

BI-METAL M42 BLADES

Bi-Metal blades are incredibly effective at cutting through notoriously hard or abrasive material, like metals with a hardness maximum of 50 on the Rockwell C scale. Simmons’ Bi-Metal blades are no exception.

Utilizing a 4% chromium alloy backing and specially hardened M42 high-speed steel tooth tips, these blades can easily withstand the intense stress exerted upon them by high-production bandsaw machines. Bi-Metal M42 blades also last about 3-4 times longer than regular carbon steel bandsaw blades due to their harder teeth, resulting in less machine downtime from changing blades and a reduced cost per cut.

Recommended cutting applications for Bi-Metal M42 blades:

- Steel

- Stainless steel

- Space age alloys

- Hard woods

- Pallets

Consistently delivering high-quality blades has been key to Simmons’ success throughout the years. As part of our reliable welds guarantee, if a Simmons blade breaks at the weld, just send it back to us. While we cannot guarantee that we will replace Bi-Metal M42 blades, we’ll evaluate the issue and reweld the blade if possible.

We stand behind our workmanship, and even when we’re not at fault for blade issues, we frequently invest in analyzing the cause of the blade’s failure in order to educate our customers and help them correct the source of the issue in their facility.

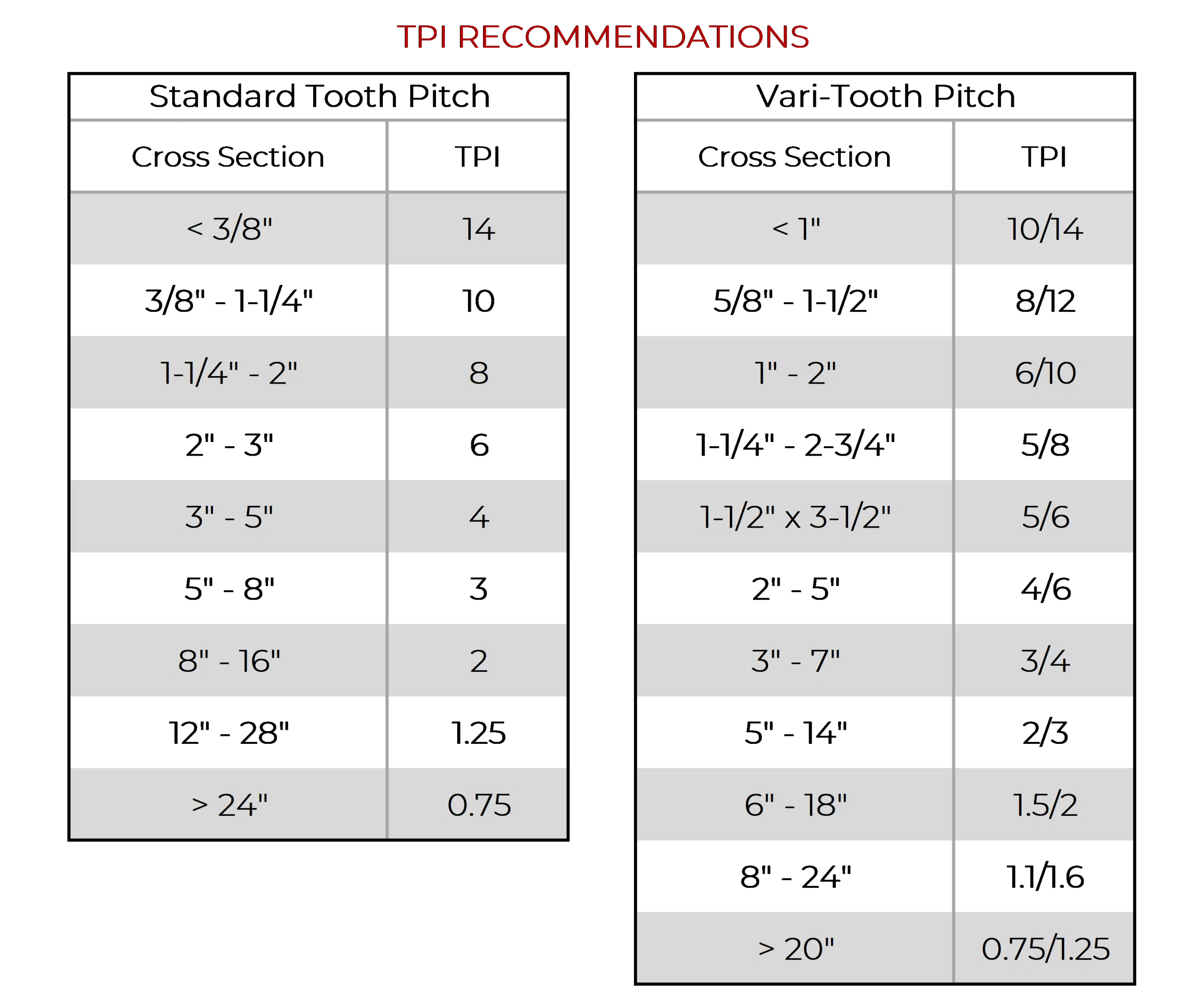

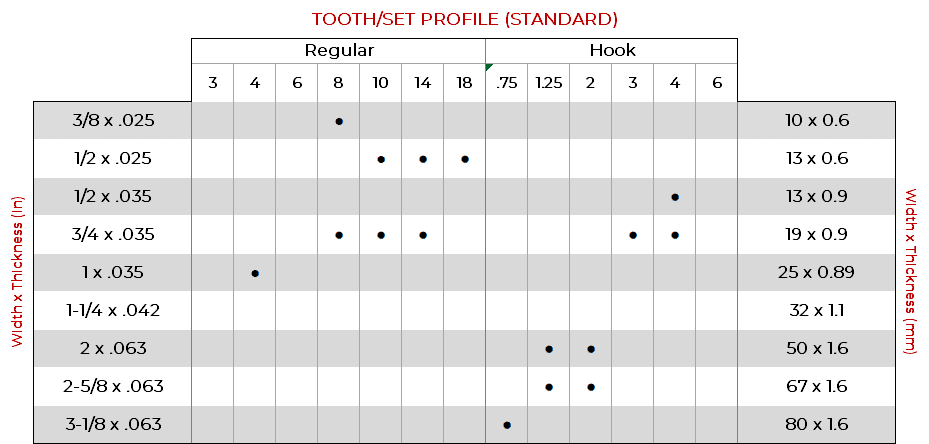

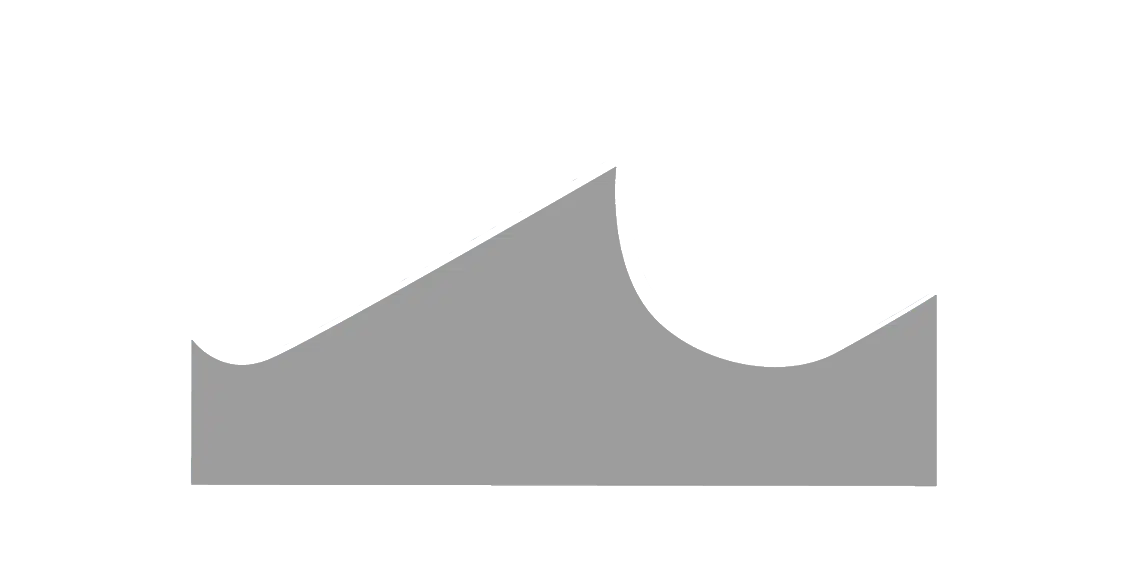

Standard Tooth

A standard tooth has a 0° cutting angle. It’s ideal for cutting steel with a high carbon content, small cross sections of steel, and thin-walled profiles and tubes.

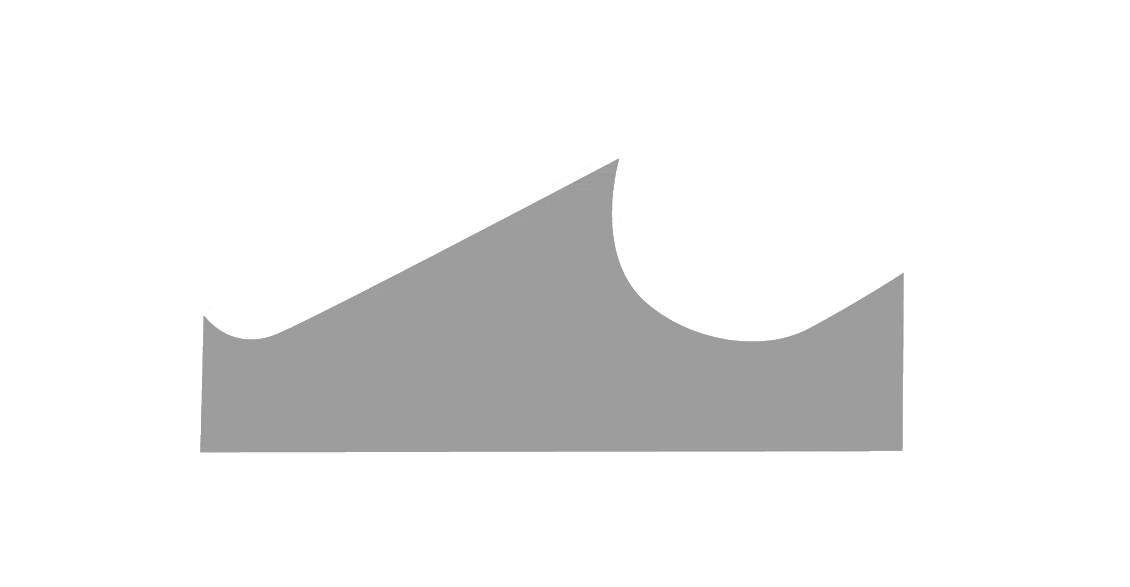

Hook Tooth

The hook tooth’s 10° positive cutting angle makes it the perfect choice for cutting through solid steel, thick-walled tubes, and higher alloy metals.

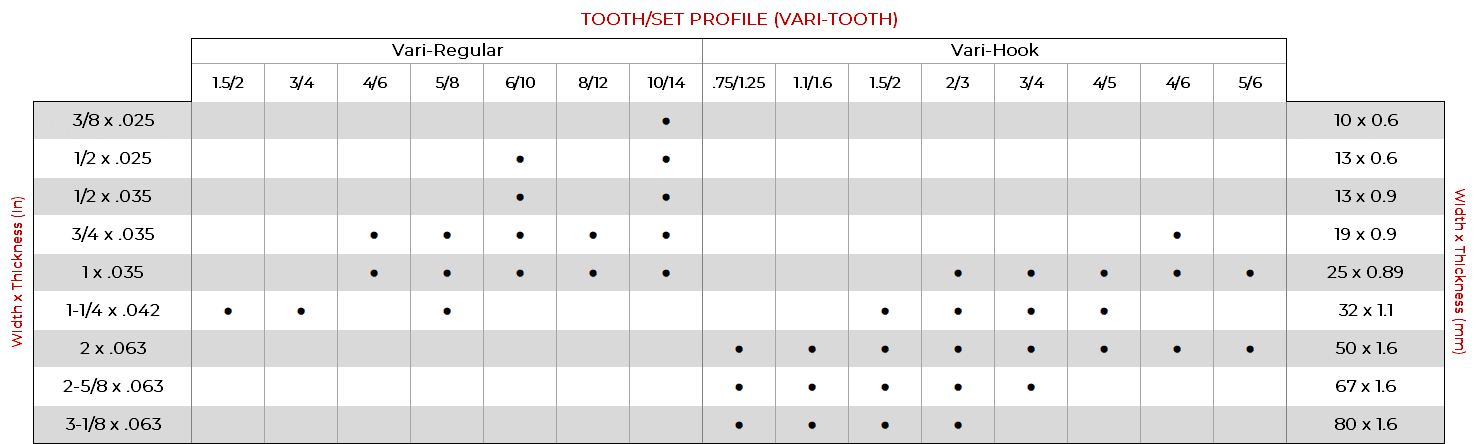

Varitooth

The varitooth has a normal tooth shape with 0° cutting angle, however the pitch (distance between teeth) varies. For example, a 5/8 varitooth blade will have alternating sections of 5 TPI and 8 TPI. This helps reduce vibrations when you are cutting larger cross-sections of material.