Simmons has manufactured bandknife and bandsaw blades for foam cutting operations for more than 75 years. In that time, we’ve learned about all different types of foam and, more importantly, which blade or edge type cuts them best for their intended purpose.

Now, we’d like to share what we’ve learned with you.

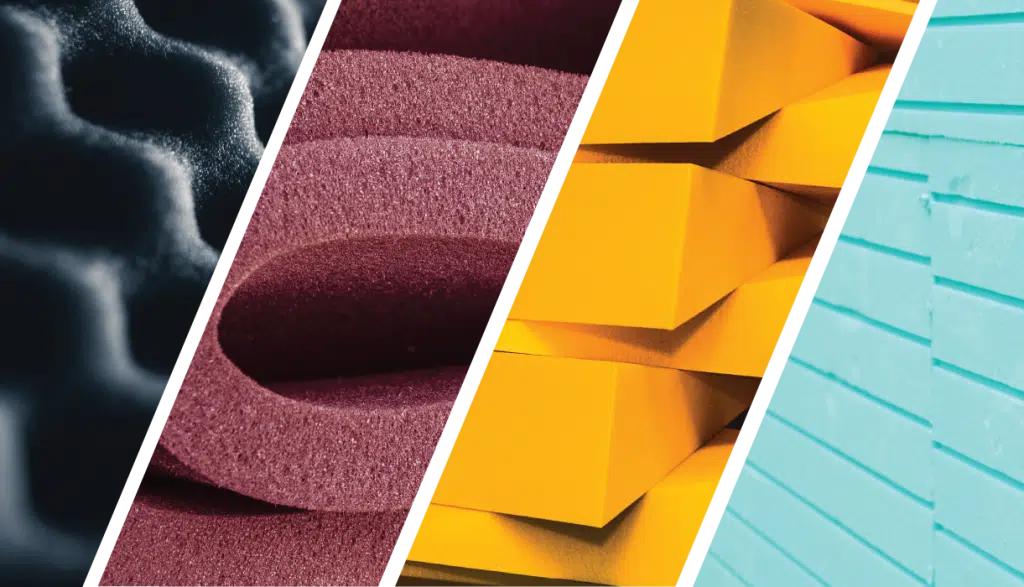

Flexible Polyurethane Foam

Flexible polyurethane foam’s (PU foam) light weight and open-cell structure have made it ideal for use in hundreds of products, including furniture cushions, mattresses, automobile seating, and medical applications. In fact, you probably encounter PU foam products several times per day without even realizing it.

PU foam’s light weight and open-cell structure make it a soft, low-density foam. If you don’t have much experience cutting low-density foams, we recommend starting with a Knife edge, Scallop, or V-Tooth bandknife blade.

Memory Foam

Viscoelastic foam, more commonly known as memory foam, is an ultra-soft, temperature-sensitive foam that molds to the shape of a body. Currently, it is mostly used to create mattresses and pillows.

Unlike other flexible PU foam, which has more of a bouncy feel to it, memory foam contains additional chemicals that increase its density and viscosity. In fact, memory foam’s density ranges from two to eight pounds per cubic foot. So, while a Knife edge blade may easily cut through a less dense piece of memory foam, you might need to upgrade to a more aggressive blade, like a Scallop or V-Tooth bandknife blade, to cut through more dense pieces of memory foam.

For those with contour cutting needs, Simmons offers a comprehensive line of CNC blades ranging from 14T to 24T with uniquely designed cutting profiles that make them ideal for cutting memory foam.

Polyethylene Foam

Similar to polyurethane foam, polyethylene foam (PE foam) is also light weight, but its closed-cell structure makes it more durable and rigid than other low to medium-density foams. PE foam is highly resistant to chemicals and moisture, and it has superior vibration dampening and insulation properties. These combined qualities led to frequent PE foam use in packaging products (fragile or otherwise).

Since PE foam has a closed-cell structure, you’ll need a slightly more aggressive blade to cut through it. We would typically recommend starting with a V-Tooth or C-Tooth bandknife blade, but if you’re looking for a cleaner finish on the cut, then a Scallop blade would likely be the way to go.

Foam Board or Rigid Foam

Foam board or rigid foam is typically used for insulation purposes in homes or commercial buildings. There are a few different types of rigid foam, but they share the same characteristics to a degree.

Rigid foam is usually quite dense to help control temperature indoors and prevent moisture accumulation, so you’ll need a sawing blade to effectively cut through it. For your convenience, we’ve listed a series of bandsaw blades from lightest to heaviest set below. If you’re not sure what you need, we recommend starting with the lightest set (Simcor) and working your way up to the heaviest set (Bi-Metal M42) only if needed.

Simcor® | SimCut® Butcher | Flexback | Hardback | Bi-Metal M42

Obviously, these are just a few types of foam that are used to create everyday products, but they represent a significant percentage of the most fabricated foam types today. If you have a question about another type of foam or want to learn more about foam cutting blades, contact us today using the button below!