Discussing SimCut Butcher Blades for Heavy-Duty Meat Cutting

26 September 2023

If your business’s operations involve cutting bone-in meats like beef, pork, fish, or poultry, then you’ll find butcher blades to be your new best friends. Produced from specialized steel with a superior tooth configuration, the SimCut Butcher blade’s longer blade life helps lower cutting costs while still yielding fast, clean cuts with minimal waste. These

- Published in Uncategorized

No Comments

Food Processing Blades: An Overview

22 July 2023

The food processing industry is one of the largest in the world. It can be broken into hundreds of sub-industries, some of which are massive in their own right. Simmons’ decades of experience in the industry have provided us with the knowledge to determine which food processing blades work best for each application, and now

- Published in Blade Tips

Simmons Teams Up With Feed My Starving Children

03 May 2023

On Saturday, April 29, Simmons’ employees along with their families spent the day volunteering at Feed My Starving Children’s location in Schaumburg, IL. This marks the third time Simmons has teamed up with Feed My Starving Children, and we’re proud to continue supporting their cause. Feed My Starving Children is a Christian non-profit organization whose

- Published in Simmons Gives Back

6 Tips for Bandsaw Maintenance & Safety

10 April 2023

We tend to think of ourselves as blade experts, but when you’ve manufactured bandsaw blades as long as we have, you tend to learn quite a bit about how bandsaw machines work as well. More accurately, you learn a lot about bandsaw maintenance and how to adhere to safety standards so that your blade doesn’t

- Published in Blade Tips

5 Things to Look for in a Bandsaw Blade Manufacturer

27 February 2023

If your business uses bandsaws to cut high volumes of foam, meat, cardboard, or other materials, then working with a reliable bandsaw blade manufacturer is critical to the success of your operations. For the cynics out there, we’ll be the first to say that we’re biased when it comes to this. However, in the past

- Published in Blade Tips, Uncategorized

Explaining Bandsaw Blade Performance

21 November 2022

In our previous video blog, we defined blade life and discussed the importance of knowing your blade’s cost per cut. However, while blade life is an extremely important factor to consider when purchasing a blade, it’s not the only one you should consider. Usually, pricing is the first thing blade users care about. In other

- Published in Blade Tips

Explaining Blade Life & Cost Per Cut

03 November 2022

If you purchase blades from a manufacturer like Simmons or a bandsaw OEM, you’ve probably heard the term “blade life” at least a dozen times before. Put simply, blade life can be equated to the amount of work completed by a blade before it loses its effectiveness. While it’s typically determined on a case-by-case basis,

- Published in Blade Tips

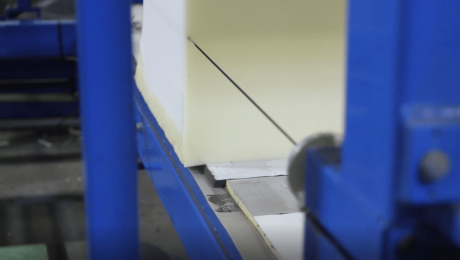

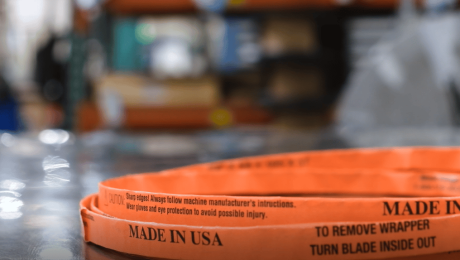

How to Quickly Uncoil & Unwrap Butcher Blades

21 September 2022

If you’re not someone who handles butcher blades on a daily basis, uncoiling and unwrapping them can become a bit of a hassle. Since Simmons strives to eliminate our customers’ hassles wherever possible, we decided to put together this video on how to quickly uncoil and unwrap your butcher blades. Press the play button below

- Published in Blade Tips

Grinding Wheel Best Practices – How to Perform a Ring Test

24 August 2022

If you’re working with bandknife or bandsaw blades, chances are you’ll eventually need to use a grinding wheel. However, before you mount a new grinding wheel, you should always perform a ring test to make sure it is in fully intact. We know you probably wish you could just start grinding away but performing a

- Published in Blade Tips

Three years ago, Simmons’ employees were given the opportunity to pay a small fee to drop their managers into a dunk tank in an effort to raise funds for St. Jude Children’s Research Hospital. The event was a splashing success and everyone involved was excited to repeat the event the following year. Unfortunately, the Covid-19

- Published in Simmons Gives Back