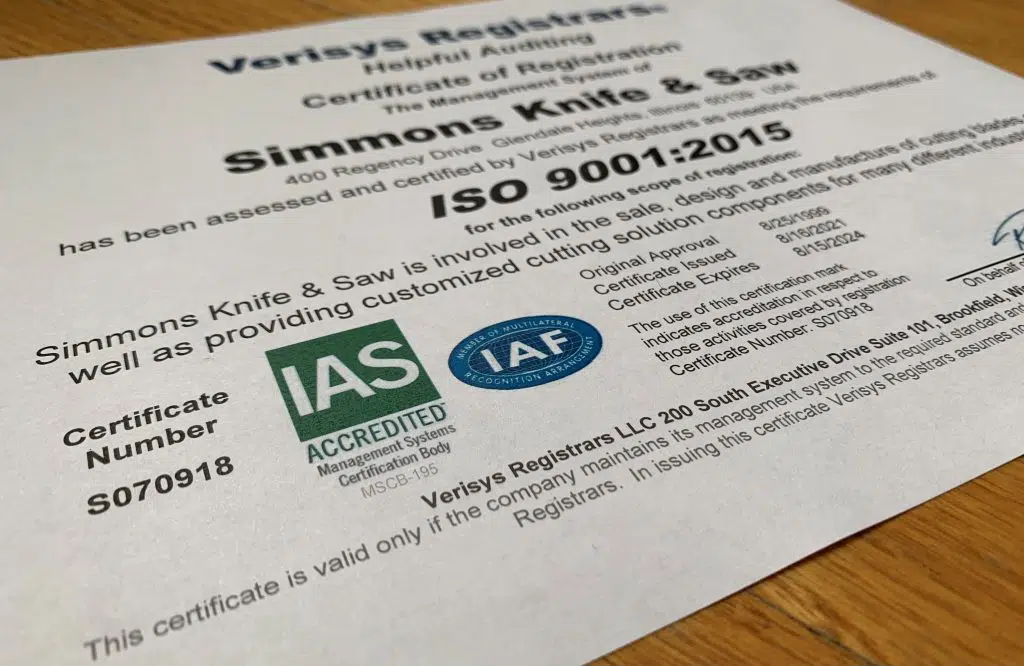

According to the International Standard Organization’s (ISO) website, “the [ISO 9001:2015] standard is based on a number of quality management principles, including a strong customer focus, the motivation and implication of top management, the process approach, and continual improvement.”

In many ways, these principles have helped to inform and shape Simmons’ own tenets of Quality Workmanship, Continuous Improvement, Superior Customer Service, and On-time Delivery. And in turn, they have benefitted our customers in several ways.

Consistently Great Quality

Any blade manufacturer can make a good blade, but not every blade manufacturer can consistently make good blades. That’s why our team always performs inspections of incoming steel, routinely inspects manufacturing processes, and subjects finished blades to random quality audits to ensure our products meet or exceed our customers’ expectations each and every time.

Product & Process Improvements

Simmons New Product Development group meets on a bi-weekly basis to ensure we’re developing blades that meet the current needs of the market and, by extension, our existing customers. We also use tools like KATA and the Lean Enterprise to identify and eliminate wasteful (or non-value adding) activities and streamline manufacturing processes.

Timely Order Fulfillment & Communication

Simmons’ production control department constantly monitors the company’s operational performance to process orders in an efficient, timely manner. Our on-time delivery rate exceeds 98%, but on the rare occasions where on-time delivery isn’t a possibility, we do our best to provide a mutually acceptable solution to meet our customers’ needs, such as offering a comparable item or shipping a partial quantity.

Knowledgeable Sales & Customer Service Team

Through the use of real-time production reporting and scheduling, our customer service department has visibility to the status of every order currently in our system, and they can pull that information at a moment’s notice. This ensures that our customer service representatives have the answers our customers need when they need them.

ISO 9001 can be used by any organization, regardless of size or industry. It is somewhat coincidental that the ISO’s principles align so well with Simmons’ tenets, but, at its core, Simmons has always been about meeting our customers’ expectations with high quality products while simultaneously aiming to raise the bar with each consecutive order. That’s what our company was founded upon, and it’s how we continue to handle business today.

For more information about how Simmons’ ISO certification benefits our customers, contact us today!