Imagine finding the perfect bandsaw blade. One that’s capable of cutting through all types of material at a faster rate than any other blade on the market. Sounds nice, right? Unfortunately for everyone, it doesn’t exist…yet. So, until our engineers design this blade (we’re sure it’s only a matter of time), the best we can do is leave you with some advice for choosing the right blade for your business’s operations.

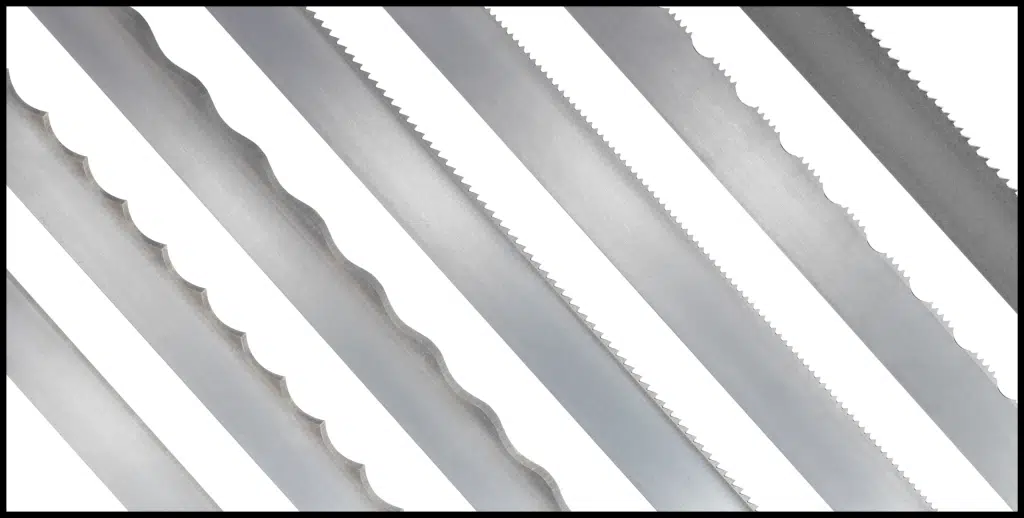

Slicing Blades

Slicing blades are best for, well, slicing through material. They typically pair well with low to medium-density applications. If you’re working with product that requires a clean finish, then a slicing blade is truly your best option as the blade will smoothly penetrate material without ripping, tearing, or wasting any of it unnecessarily.

A Knife edge blade will always offer the cleanest cut out of any blade. However, if the smooth, sharpened edge of the Knife isn’t aggressive enough, a Scallop blade would be the sensible next choice. A favorite of foam fabricators, insulation manufacturers, packaging OEMs, and boneless meat processors, the Scallop blade is incredibly versatile. Its razor-sharp pitch makes it a great fit for a variety of applications, but those working with fibrous material may want to substitute it for a Wavy blade, which doesn’t have tips that pull at individual fibers, leaving you with a ragged cut.

Cutting Blades

If your specific application calls for a slightly more aggressive blade, you’ll likely want to use a toothed blade without set (AKA a cutting blade). Toothed blades like the C-Tooth, V-Tooth, and Razorback blades provide more of a bite into the material being cut. However, while they are considered more aggressive than slicing blades, a toothed blade without set still doesn’t create much dust. This makes these blades ideal for cutting low to medium firm/dense foams such as polyurethane or polyethylene.

Wondering how many teeth per inch is best for your specific application? Here’s a good rule of thumb: The larger the tooth, the more aggressive the cut, which allows for a faster cut. If product finish or the amount of product lost is a concern, a smaller tooth will usually give a cleaner cut.

Sawing Blades

When it comes to cutting metal, wood, or other similarly dense products, you’ll need a saw blade like the Bi-Metal M42, Flexback, or Hardback blade. These blades have teeth with set that carve or rip into material in order to help the blade penetrate more easily.

Looking for a lighter-duty saw blade that works well with firm/dense foams, bone-in meats, lighter metals such as aluminum, or cardboard? Our Simcor®, Simcut® Butcher, and Honeycomb blades are all thinner with slightly less set than Flexback or Hardback blades, potentially making them a great fit for such applications.

Generally, the same theory of a larger tooth for a more aggressive/faster cut still applies. However, be careful when choosing a metal or wood cutting bandsaw blade as too large of a tooth could cause the teeth to break off easily and too small of a tooth will not cut the product effectively.

If you’re feeling like that was a lot of technical info to take in all at once, you’re probably not alone. When in doubt, please reach out to one of Simmons’ Regional Sales Managers. Not only can they provide blade recommendations for your applications, but they can also help diagnose issues you have with your band saw machines that might be affecting your current blades.

Interested in learning more about which bandsaw blade is right for your cutting needs? Click the button below to contact us today!