Have you ever wondered if you’re using the right foam cutting blade? What if you could find a blade that provided better cutting results for your foam fabrication operations? What if that blade was more cost-effective and reduced machine downtime? There are plenty of foam cutting blades on the market that could offer benefits like these. Let’s break some of them down.

CNC Blades

CNC blades are a necessity for foam fabrication operations with contour-cutting needs. Simmons offers cut-to-length CNC blades for oscillating machinery and welded CNC band blades for continuous band saws. Available CNC blade edge types include Knife, Micro-A, Razorback, V-Tooth, and V-Tooth Flat. We recently published a blog with much more detailed information about our CNC blades, which you can find here.

Generally speaking, most foam fabricators with contour-cutting needs find success using one of our previously mentioned CNC edge types. However, that’s not always the case, especially if you’re cutting through particularly dense foam. When you need something tougher, we recommend trying Simmons’ DuraBand CNC blades. Made from specialized steel and designed with maximum durability in mind, DuraBand CNC blades last longer compared to other carbon variants of steel and retain their sharpness for longer too.

Side note: If your foam cutting blades are wearing out too quickly, Simmons can harden the edge of your blades to extend blade life and retain a sharp cutting edge for a longer period. This is available for all CNC blades. You can learn more about the benefits of heat treating your blades here.

-Eliminates need for resharpening? Yes

Knife Edge Bandknife Blades

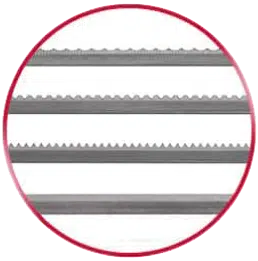

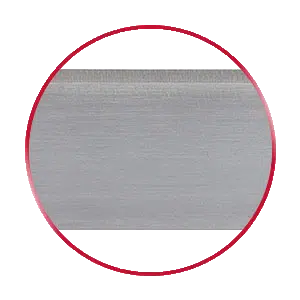

Knife Edge blades, along with V-Tooth blades, are one of the most common types of blades used in foam cutting operations. Knife Edge blades qualify as slicing blades, which means that they won’t remove any material or create dust throughout the entirety of the cut. They are also perfect for slicing through flexible foams, as long as you’ve got a sharpening system on your machine to keep the blade’s edge sharp enough to cut without pulling or tearing at the foam.

-Eliminates need for resharpening? No

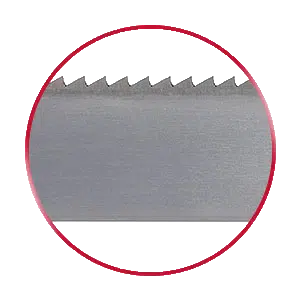

V-Tooth Bandknife Blades

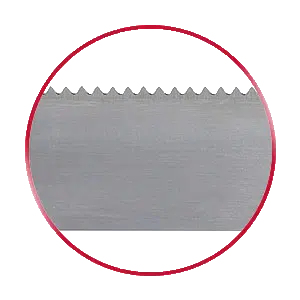

V-Tooth blades are the most popular choice for cutting low to medium-density foams. If you’re cutting flexible foam and your machine isn’t equipped with a blade sharpener, you may be better off opting for a V-Tooth blade over a Knife Edge. They’re also a great blade to start with if you’re in the foam fabrication industry and aren’t quite sure what you’re looking for.

The V-Tooth blade’s teeth work to penetrate material, which provides a faster cut than a standard Knife Edge or Scallop blade. Since it does provide a more aggressive cutting action, it will likely create some dust as it cuts but not an amount to cause concern.

-Eliminates need for resharpening? Yes

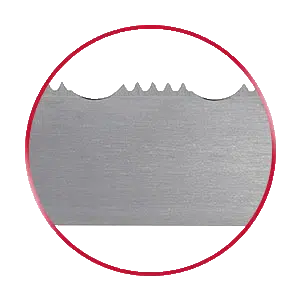

Scallop Bandknife Blades

Foam fabricators typically like the Scallop blade because it offers the best of both worlds, combining the slicing action you’d get from a Knife Edge blade with penetrating tips, much like a toothed blade. Each scallop’s individually ground, razor-sharp edge allows the blade to quickly slice through all types of flexible foam, leaving a smooth finish without creating much dust.

-Eliminates need for resharpening? Yes

You can learn a lot more about Simmons’ Scallop bandknife blades by checking out one of our recent blog posts here.

C-Tooth Bandknife Blades

If you’re in need of a more aggressive toothed blade than the V-Tooth, look no further than the C-Tooth blade. Perfect for cutting through dense or rigid foams, the vertical edge of the C-Tooth is designed to enter the product first. Running the blade in the opposite direction is another option, providing a gentler slicing action.

-Eliminates need for resharpening? Yes

Razorback Bandknife Blades

Razorback blades combine the cutting action of the V-Tooth blade with the slicing action of the Scallop blade. The Razorback blade’s large gullet allows deeper penetration of rigid or less flexible foams, while still keeping dust creation to a minimum. Some foam fabricators have been known to choose the Razorback blade over a blade with set teeth in order to avoid a rough surface finish.

If you like this edge type but need a blade for contour-cutting operations, then you’re in luck. Simmons’ offers the Razorback edge type in CNC form for all your contour-cutting needs, which you can learn more about here.

-Eliminates need for resharpening? Yes

Wavy Bandknife Blades

Similar to Scallop blades, Wavy blades also eliminate the need for a grinding wheel or stone. However, while Scallop blades come to a defined point, the edge of a Wavy blade is made up of a series of smooth crests or waves, hence the name. Wavy blades are a great choice for cutting flexible polyurethane foams and fibrous material.

-Eliminates need for resharpening? Yes

Finding the Right Blade for You

Finding the right foam cutting blade for each cutting application isn’t an exact science. There’s going to be some trial and error as you narrow your options down. The process can certainly be frustrating, but it can also be made easier by partnering with an experienced blade manufacturer, like Simmons.

Contact us today to optimize your foam-cutting operations!