If you purchase blades from a manufacturer like Simmons or a bandsaw OEM, you’ve probably heard the term “blade life” at least a dozen times before. Put simply, blade life can be equated to the amount of work completed by a blade before it loses its effectiveness.

While it’s typically determined on a case-by-case basis, blade users first look to the amount of material a blade can cut before failing when determining blade life.

Amount

The more material a blade can cut, the better its performance is considered. In this instance, the amount of material a blade can consistently cut through before failing is directly related to the length of its life.

Blade manufacturers like Simmons can estimate how long their products will last. However, tracking the number of hours, days, or weeks a blade is on the machine is the only surefire way to determine blade life for yourself. Once you’ve done that, you’ll see that the real value of a blade lies in its cost per cut.

Cost per cut

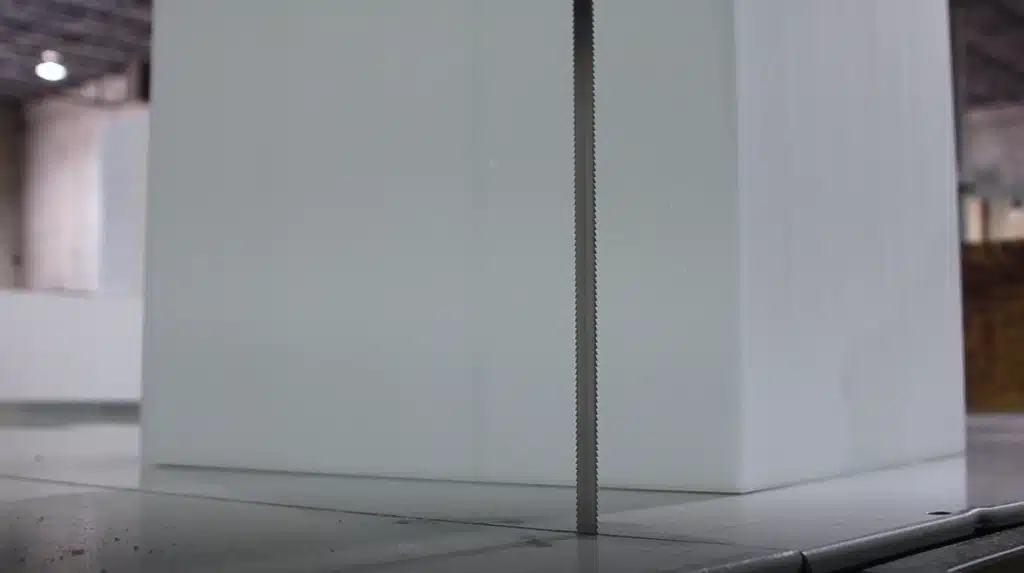

A blade’s cost per cut is exactly what it sounds like. Let’s say you have the option of choosing between a $10 blade and a $20 blade for cutting sheets of foam.

The $10 blade provides 100 clean-cut sheets of foam before failing or beginning to mar the foam. That’s not bad, but the $20 blade provides you with 300 clean-cut sheets of foam before failing, which is a significantly lower cost per cut than the $10 blade.

So even though you might be paying double the cost upfront, you end up paying less for higher output in the long run. Not to mention all the machine downtime you’ll avoid as well. Time is money after all.

For more information on blade life or industrial cutting solutions, check out the rest of our blog or contact Simmons today!