Rigid foams—like expanded polystyrene (EPS), polyurethane, and polyethylene—pose unique challenges when it comes to cutting. Their dense structure requires durable blades with precise control to achieve consistent results. Simmons Knife & Saw offers a variety of saw blades for rigid foams that are specifically designed to meet these demands.

Let’s take a closer look at several saw blade options that are well-suited for cutting rigid foam, including Flexback, Hardback, Simcor®, and Wire blades. Each blade type brings its own strengths to the table depending on your cutting needs.

Flexback Blades

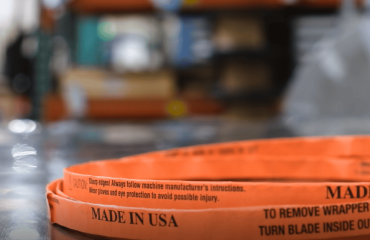

Manufactured from high-carbon steel with hardened tooth tips, the Flexback blade is one of the most versatile bandsaw blades in Simmons’ catalog. Compared to the Hardback blade, the Flexback blade’s more flexible backing increases its fatigue resistance while still providing consistently even cuts. It’s ideal for straight or radius cuts in a variety of cutting applications, including high-density and rigid foam, wood, metal, and more.

Flexback blades can also be manufactured with a normal tooth, hook tooth, or skip tooth set. You can click here for more detailed information on Flexback blades.

Hardback Blades

Manufactured from high-carbon steel, the Hardback blade is ideal for cutting through high-density and rigid foams, wood, and non-ferrous metals. Its hardened backing allows the blade to be tightened to a greater tension than the Flexback blade. This greater tension, coupled with individually hardened teeth, leaves the Hardback blade as the unrivaled choice for truly straight cuts through even the most rigid foam applications.

Similar to Flexback blades, Hardback blades can also be manufactured with a normal tooth, hook tooth, or skip tooth set. Click here for more details.

Simcor Blades

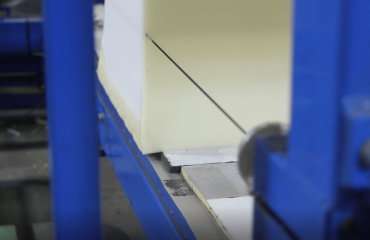

The Simcor® blade was created in response to Simmons’ customers requesting a blade that was effective at cutting through heavy, rigid foam.

Standard Simcor blades have 10 teeth per inch (TPI) and feature a modified C-Tooth cutting edge with a lighter set than you’ll find in most carbon saw blades. Coupled with a hardened cutting edge, this allows the blade to rip through incredibly dense material while still keeping dust and material waste to a minimum.

You can learn more about Simcor blades here.

Wire Blades

Wire blades are used to cut intricate patterns and shapes out of foam and other materials. Wire blades consist of several individual strands of wire wrapped around an inner core of wire strands. The outer wire wrap forms a pattern. The specific pattern that wires are wrapped in is what makes the blade more abrasive or less abrasive. The more abrasive the Wire blade, the more aggressive the cut when the blade is pulled through its respective application.

Simmons offers Wire blades in several levels of abrasiveness for a wide range of products. For applications that require a high level of abrasiveness, Simmons can provide Wire blades produced from tungsten steel.

To learn more about Wire blades, click here.

Choosing the right blade for cutting rigid foam largely depends on your material and desired cut quality. Whether you’re looking for the durability of a Hardback blade, the versatility of a Flexback, the heavy-duty performance of a Simcor®, or the precision of a Wire blade, Simmons has a solution to match. If you’re unsure which blade will meet the needs of your cutting operations, our team is available to help you select the best fit.

Contact us today to learn more about saw blades for rigid foams or to request a quote!