Ever wonder how to make your blades last longer and perform better? The answer lies in a key step of the manufacturing process: heat treating.

Why Heat Treating Matters

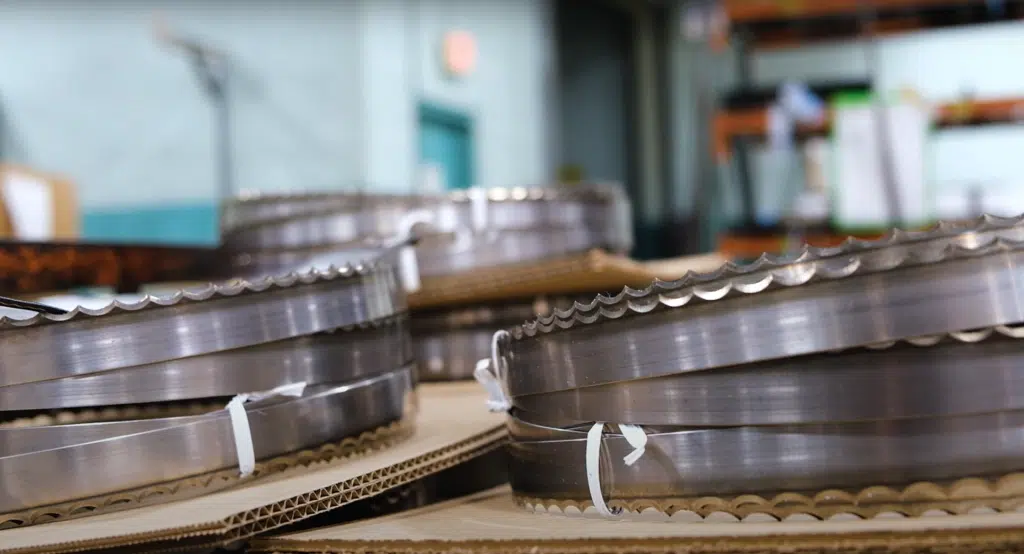

When we talk about heat-treating bandsaw blades, we’re not referring to the entire blade. Heat treatment usually targets the edge or teeth of a blade. This increases the hardness of the blade’s edge, making it sharper and extending its useful life. Essentially, heat-treating helps your blades retain their cutting edge, so your blades stay sharper longer, even after heavy use.

When to Heat Treat Your Blades

Depending on their intended use, we heat treat many of our blade types, including C-Tooth, CNC, Razorback, Scallop, V-Tooth, and Wavy blades. The degree of hardness we aim for—and where we apply it—depends on the blade’s intended use. For instance, Hardback blades are typically heat-treated on both the teeth and the backer of the blade. This increases beam strength, making Hardback blades perfect for cutting non-ferrous metals like brass, lead, and bronze. In contrast, Flexback blades are heat-treated only on the teeth. This keeps the backer flexible, which is ideal for contour cutting or working with comparatively softer materials like plastic and wood.

We typically recommend heat-treating blades that are going to be used to cut through abrasive applications like rough foams, scouring pads, sandpaper sponges, and fiberglass. Tough materials like these can quickly wear down a blade, but with heat treating, you’ll notice a big difference in longevity. That means you won’t have to replace your blades as often, which will reduce your machine downtime and keep your operations running smoothly.

Striking A Balance

The goal of heat-treating is to harden the teeth or edge of the blade while maintaining flexibility in the body. But there’s a balance—too much heat treating, and the blade becomes brittle rather than strong. That’s why we carefully control the process to ensure you get a blade that fits your needs.

The Bottom Line

Heat treatment can be a game-changer when it comes to extending the life of your blades. Whether you’re cutting through abrasive materials or looking for a blade that can handle precision tasks, heat treating your blades will ensure they stay sharper and last longer.

Want to see if heat-treating your blades is the right move for your cutting operations? Contact us today!