In 2020, U.S. commercial fisheries hauled in approximately $4.8 billion worth of fish and seafood across all ports. The fact that that figure only concerns fish and seafood caught in U.S. waters speaks to the massive size and growth of the fish and seafood processing industry.

In fact, according to market research firm The Insight Partners, the global seafood market is expected to reach $201.25 billion by 2028. Based on that information, it would seem safe to say that equipment like fish and seafood processing blades will be in demand for quite some time.

Smaller processing plants typically process their fish and seafood manually (this is especially common with freshwater fish). This requires their employees to use a variety of handheld knives to scale, de-head, and gut fish. Simmons hasn’t manufactured any handheld knives since the 1940s, but we can supply all the bandsaws and knives that seafood processors need for automatic processing operations.

Blades for Automatic Seafood Processing Machines

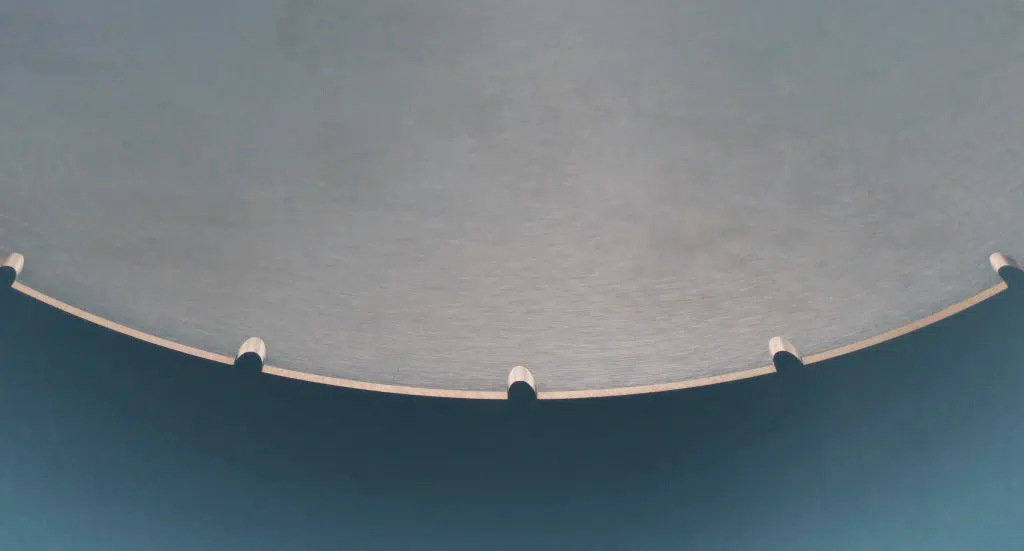

Simmons can provide knives for automatic filleting, skinning, de-heading, portioning, and slicing operations as well as shrimp deveiners, crab leg cutters, frozen cutters, and ultrasonic cutters.

All Simmons’ seafood processing knives are made from high-quality 300 or 400-series stainless steel and can be used in the processing of saltwater fish, freshwater fish, shellfish, and packaging operations. If necessary, we can provide seafood processing knives made from 17-4 PH stainless steel. We can also passivate or electropolish your knives as needed.

Improved Corrosion Resistance

In addition to 17-4 PH stainless steel, Simmons can provide seafood processing knives made from D2 HcHc, M2HSS, carbide materials, and other specialty materials upon request.

Some of our customers in the seafood processing industry do their processing in extreme locations like coastal regions and even on fishing boats in the middle of the ocean. Due to the saltwater environments in those locations, these processors often struggle with their knives rusting too quickly. Some processors have even seen brand-new knives start to rust in less than 24 hours.

Needless to say, changing processing knives every 24 hours or less is inefficient. That’s why we work with our customers to find the right steel makeup for their operations and environment to reduce the rate at which their knives corrode. Less frequent corrosion means less machine downtime for our customers and more money in their pockets at the end of the day.

From Processing to Packaging

Assuming you’ve taken a walk through your local grocery store before, you know that finished seafood products come in the form of fish fillets, steaks, or loins, ready-to-cook or dressed fish, shucked and cooked shellfish meat, etc. These finished products are usually packaged using cans, multi-layer film, stand-up pouches, and vacuum packaging.

Simmons keeps many standard packaging knives in stock to be able to deliver them to our customers as quickly as possible. You can find some of the packaging knives we regularly stock here.

If we don’t have what you need in stock, we can always custom-manufacture packaging knives to your exact specifications.

Wrapping It Up

The staggering growth projected for the global seafood market underscores the ongoing demand for reliable and efficient seafood processing knives like Simmons’. We pride ourselves on consistently crafting high-quality knives that outperform and outlast our competitors, no matter the type of processing being done or environmental conditions.

We offer replacement knives for the following seafood processing OEMs:

- Arenco

- Baader

- CP Food Machinery

- Geba

- Grasselli

- Kroma

- Marel

- Norfo

- Pelagic

- Pisces

- Prawnto

- Ross Industries

- Sodeva

- Townsend

- Trio

- Vemag

If you didn’t see your OEM on this list, don’t worry. We can manufacture replacement knives for most OEM machines as long as you can provide your OEM machine model and knife part number or a print/sample of your current knife.

Contact Simmons today to learn more about how we can help you get the most out of your seafood processing operations!