TISSUE PROCESSING BLADES

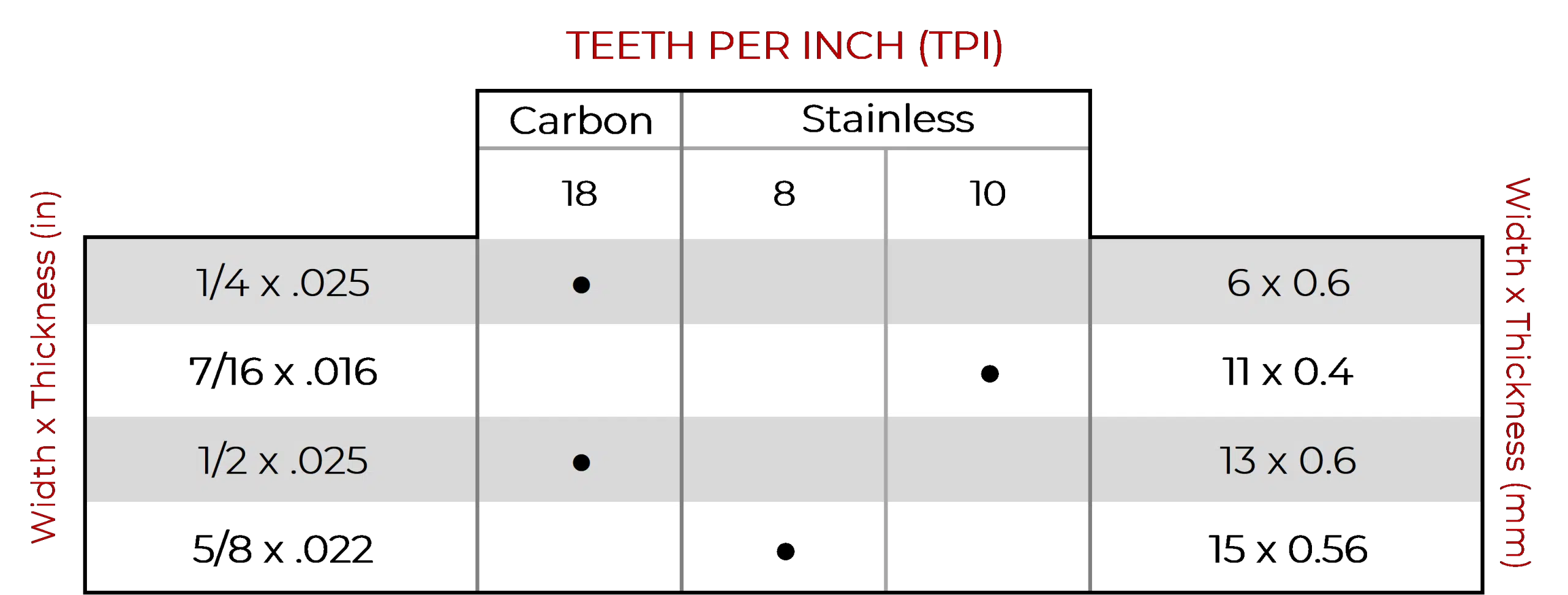

Simmons’ tissue processing blades can be produced from either high carbon steel or stainless steel. Featuring unique tooth shape and set pattern options, tissue processing blades are aggressive enough to cut through bone and tissue yet also precise enough to not damage or waste any donor tissue along the way.

Tissue processing customers who trial Simmons’ blades typically report longer blade life and longer lasting sharpness. They also report less oil residue on the blades, which is a direct result of Simmons’ adherence to the strict cleaning and packaging protocols set by tissue processors.

Recommended cutting applications for Tissue Processing blades:

- Musculoskeletal allografts

Consistently delivering high-quality blades has been key to Simmons’ success throughout the years. As part of our reliable welds guarantee, if a Simmons blade breaks at the weld, just send it back to us. We’ll evaluate the issue and replace the blade if possible.

We stand behind our workmanship, and even when we’re not at fault for blade issues, we frequently invest in analyzing the cause of the blade’s failure in order to educate our customers and help them correct the source of the issue in their facility.

In order to further extend the life of tissue processing blades, we’ve made hardening the cutting edge of the blade a standard part of the production process.

*Does not apply to stainless steel blades.*