WIRE BLADES

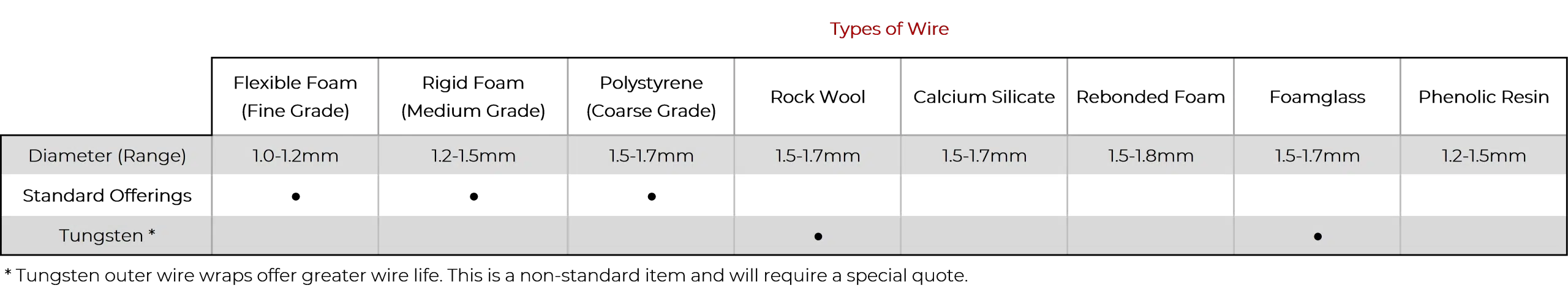

Wire blades are used to cut intricate patterns and shapes out of foam, rock wool, foam glass, and other materials. Wire blades consist of several individual strands of wire wrapped around an inner core of wire strands. The outer wire wrap forms a pattern. The specific pattern that wires are wrapped in is what makes the blade more abrasive or less abrasive. The more abrasive the Wire blade, the more aggressive the cut when the blade is pulled through its respective application. For applications that require a high level of abrasiveness, Simmons can provide Wire blades produced from tungsten steel.

Simmons offers Wire blades in several levels of abrasiveness for a wide range of products. However, due to the way they’re manufactured, rolls of Wire blades are not available for order.

Recommended cutting applications for Wire blades:

- Flexible foam

- Rigid foam

- Insulation

- Pipe insulation

- Non-woven materials

- Rock wool

- Foam glass

Consistently delivering high-quality blades has been key to Simmons’ success throughout the years. As part of our reliable welds guarantee, if a Simmons blade breaks at the weld, just send it back to us. While we cannot guarantee that we will replace Wire blades, we’ll evaluate the issue and replace the blade if possible.

We stand behind our workmanship, and even when we’re not at fault for blade issues, we frequently invest in analyzing the cause of the blade’s failure in order to educate our customers and help them correct the source of the issue in their facility.

Wire blades are available in continuous lengths ranging from 1,500mm to 12,000mm.