HONEYCOMB BLADES

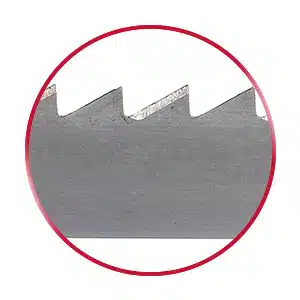

Simmons’ Honeycomb blade is the blade of choice for open cell materials where a “fuzz-free” cut is necessary. Honeycomb blades are intended to cut with the teeth facing backward. Because the blade’s tooth face is ground, we recommend a blade thickness of at least .025”. The alternating bevels on the back of the teeth help provide a more aggressive cut through fragile material without removing or damaging any of it.

Recommended cutting applications for Honeycomb blades:

- Aerospace panels

- Honeycomb made with paper, composite, aluminum, or other materials

- Packaging material

Consistently delivering high-quality blades has been key to Simmons’ success throughout the years. As part of our reliable welds guarantee, if a Simmons blade breaks at the weld, just let us know and we’ll replace that blade for you.

We stand behind our workmanship, and even when we’re not at fault for blade issues, we frequently invest in analyzing the cause of the blade’s failure in order to educate our customers and help them correct the source of the issue in their facility.

As part of our Honeycomb blade production process, Simmons offers an additional option to harden the cutting edge of the blade in order to extend overall blade life.

*Does not apply to double edge blades.*

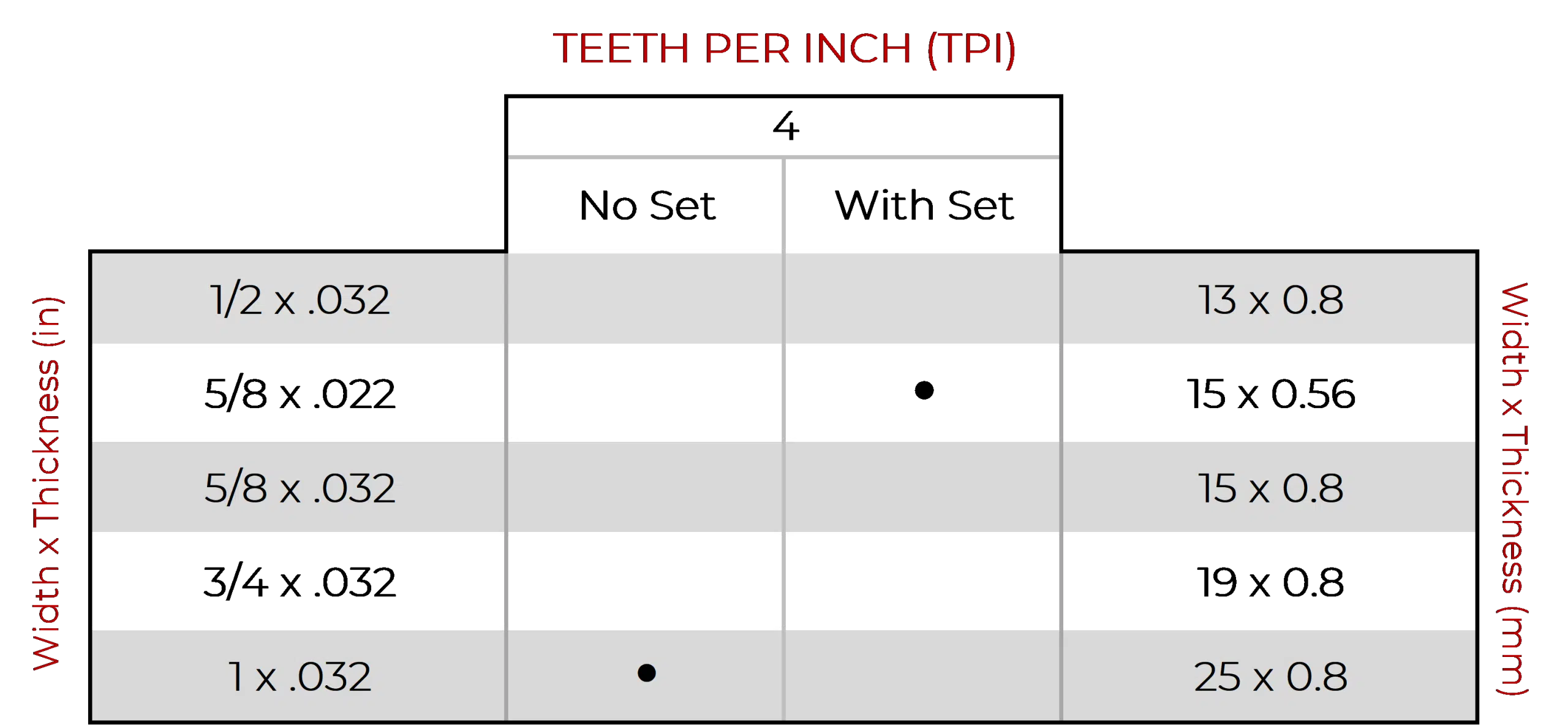

All standard Honeycomb blades have 4 TPI. Simmons also offers the option of a set tooth (or bending each tooth left or right of the center of the blade) for single edge blades.