FURNITURE BAND BLADES

While still manufactured from a single piece of high carbon steel with individually hardened tooth tips, Simmons’ Furniture Bands are actually a bit thicker than the Flexback blade. That increased thickness makes for a stiffer blade, allowing for a more controlled cut as a result.

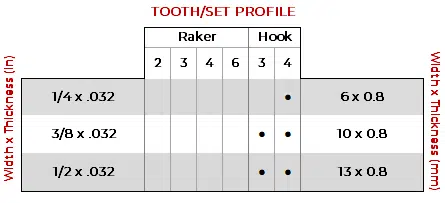

The Furniture Band’s aggressive hook teeth and alternate (ETS) set pattern were designed with faster cutting and longer tooth tip life in mind. Combine that with the blade’s wider kerf and ability to withstand heavy twisting, and you’re left with the perfect blade for the contour control required in furniture manufacturing.

Recommended cutting applications for Furniture Band blades:

- High-density foam

- Wood

- Chipboard

- Plywood

- Cardboard

Consistently delivering high-quality blades has been key to Simmons’ success throughout the years. As part of our reliable welds guarantee, if a Simmons blade breaks at the weld, just send it back to us. We’ll evaluate the issue and replace the blade if possible.

We stand behind our workmanship, and even when we’re not at fault for blade issues, we frequently invest in analyzing the cause of the blade’s failure in order to educate our customers and help them correct the source of the issue in their facility.

Hook Tooth

The hook tooth’s 10° angle makes for a faster, more aggressive cut through wood products.