APEX BLADES

Upon a first glance at the Apex blade, you’ll find the design looks similar to Simmons’ Scallop blade. The main difference between the two is that Apex blades utilize a straight grind. In comparison, the gullets of a Scallop blade are individually ground to slice through material with less effort and result in a cleaner finish. However, the Apex blade’s carbon steel makeup still offers a more penetrative cut than both Knife Edge and V-Tooth blades.

Bottom line, if you like the Scallop blade but are looking for a more economical option, the Apex blade may be the best fit for your operations.

Recommended cutting applications for Apex blades:

- Low-density foam

- Medium-density foam

- Gel foam

- Memory foam

Consistently delivering high-quality blades has been key to Simmons’ success throughout the years. As part of our reliable welds guarantee, if a Simmons blade breaks at the weld, just let us know and we’ll replace that blade for you.

We stand behind our workmanship, and even when we’re not at fault for blade issues, we frequently invest in analyzing the cause of the blade’s failure in order to educate our customers and help them correct the source of the issue in their facility.

Double Edge Single Bevel (ASSB)

Single Edge Single Bevel (ASB)

Double Edge Double Bevel (ADDB)

Single Edge Double Bevel (ADB)

As part of our Apex blade production process, Simmons offers an additional option to harden the cutting edge of the blade in order to extend overall blade life.

*Does not apply to double edge blades.*

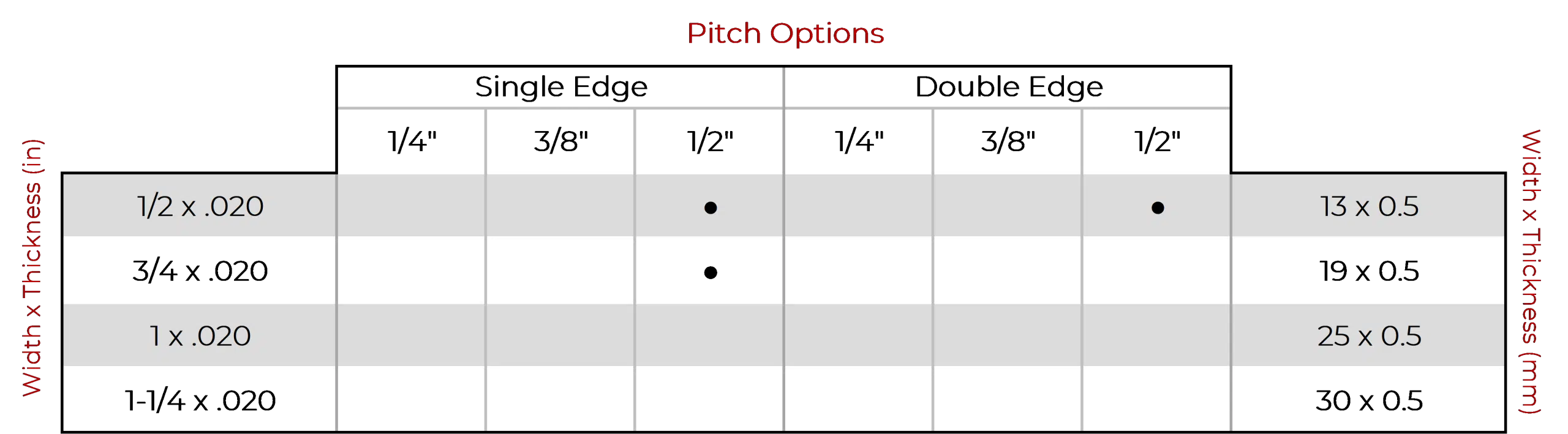

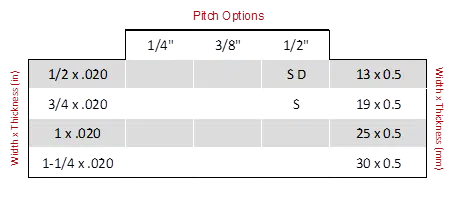

Pitch is the distance from point to point. Standard Apex blades have a ½” pitch. However, we also offer a ¼" and 3/8” pitch.