- HOME

- INDUSTRIES

- ABOUT US

- PRODUCTS

- APEX BLADES

- B-3 BLADES

- BI-METAL M42 BLADES

- BREAD SLICING BLADES

- BUTCHER BLADES

- BUTCHER DURASPLIT CARCASS BLADES

- C-TOOTH BLADES

- CARBIDE GRIT BLADES

- CARBIDE TIPPED BLADES

- CNC BLADES

- FILED-IN-THE-GULLET BLADES

- FLEXBACK BLADES

- FURNITURE BAND BLADES

- FOOD SLICING BLADES

- HARDBACK BLADES

- HONEYCOMB BLADES

- KNIFE BLADES – NARROW

- KNIFE BLADES – WIDE

- RAZORBACK BLADES

- SCALLOP BLADES

- SEAFOOD PROCESSING KNIVES

- SIMCOR® BLADES

- SPECIAL NOTCH BLADES

- TISSUE PROCESSING BLADES

- V-TOOTH BLADES

- WAVY BLADES

- WIRE BLADES

- GRINDING WHEELS & ACCESSORIES

- PACKAGING KNIVES – CUP & TRAY SEALING MACHINES

- PACKAGING KNIVES – HORIZONTAL FORM, FILL & SEAL MACHINES

- PACKAGING KNIVES – VACUUM PACKAGING MACHINES

- PACKAGING KNIVES – VERTICAL FORM, FILL & SEAL MACHINES

- PACKAGING KNIVES – CASE SEALERS

- REQUEST A QUOTE

- NEWS & VIEWS

- CONTACT US

Got a few minutes? Our experts are ready to help you find the right blade for your foam cutting operations at a moments notice.

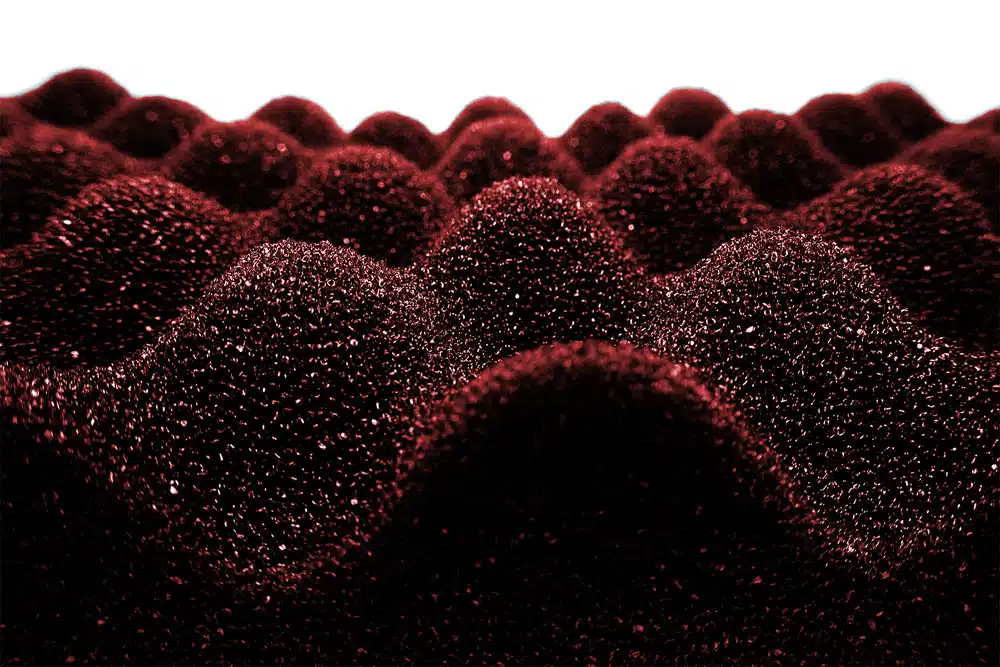

Blades for Low-Density Flexible Foams

Find bandsaw blades for cutting foam rubber, polyurethane foam, and other low-density foams.

When you’re working with less dense flexible foams, a Knife Edge blade is the way to go.

Simmons’ Knife Edge bandknife blades remove no material, providing you a clean cut all the way through without ripping or tearing the foam.

Need a more aggressive blade? Try our Scallop bandknife blades or Wavy bandknife blades. The sharpened tips of each penetrate the foam first so that the blade can slice through without pulling at or ripping the material, making either the perfect choice for low- to medium-density foams.

Blades for Low-Density Flexible Foams

Find bandsaw blades for cutting foam rubber, polyurethane foam, and other low-density foams.

When you’re working with less dense flexible foams, a Knife Edge blade is the way to go.

Simmons’ Knife Edge bandknife blades remove no material, providing you a clean cut all the way through without ripping or tearing the foam.

Need a more aggressive blade? Try our Scallop bandknife blades or Wavy bandknife blades. The sharpened tips of each penetrate the foam first so that the blade can slice through without pulling at or ripping the material, making either the perfect choice for low or medium-density foams

Blades for Medium & High-Density Flexible Foams

Minimize dust and product loss with bandknife blades for cutting medium & high-density foams.

Try a toothed bandknife blade when you need to kick things up a notch.

Simmons’ V-Tooth, C-Tooth, and Razorback bandknife blades are more aggressive than our slicing blades. Best used with low to medium-density foams, these blades create minimal dust while removing little to no material with every cut. Oh, and they eliminate the need for a sharpening system.

If a fine finish on your cut is critical, Simmons’ Scallop blade creates less dust than our toothed blades while still providing an aggressive enough cut for most flexible foams, particularly high-density flexible foams like visco elastic or memory foam.

Blades for Medium & High-Density Flexible Foams

Minimize dust and product loss with bandknife blades for cutting medium & high-density foams.

Try a toothed blade when you need to kick things up a notch.

Simmons’ V-Tooth, C-Tooth, and Razorback bandknife blades are more aggressive than our slicing blades. Best used with low to medium-density foams, these blades create minimal dust while removing little to no material with every cut. Oh, and they eliminate the need for a sharpening system.

If a fine finish on your cut is critical, Simmons’ Scallop blade creates less dust than our toothed blades while still providing an aggressive enough cut for most flexible foams, particularly high-density flexible foams like visco elastic or memory foam..

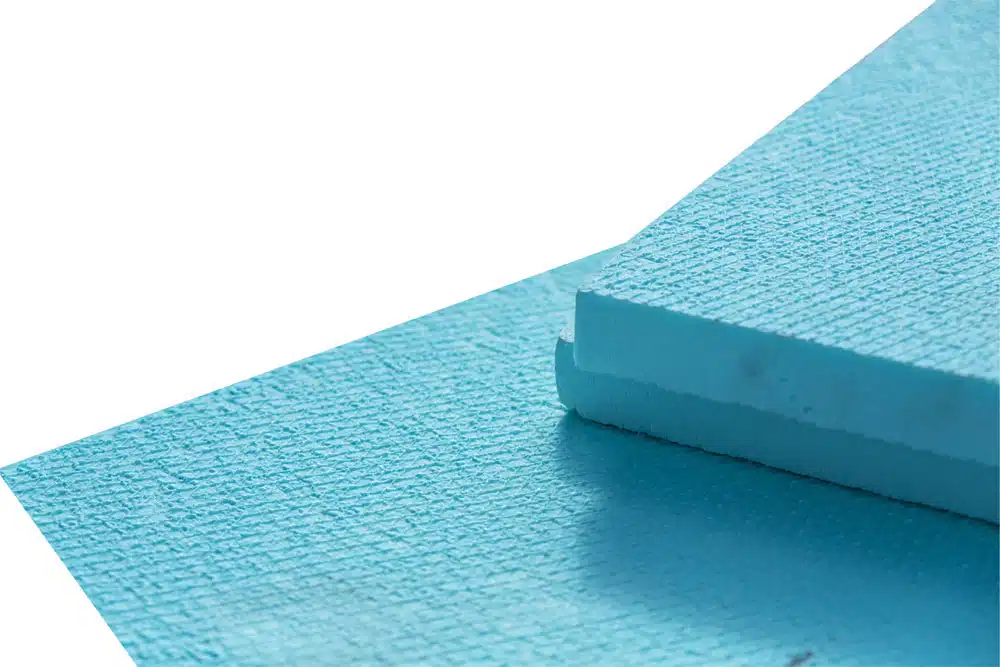

Blades for Rigid Foams

Choose the right rigid foam saw blades for clean cuts every time.

When you’re working with rigid foams, it’s time to get serious and use a sawing blade, or a blade with a set.

A blade with a set is really just a blade with teeth that extend beyond the blade. Why is this important? We’re glad you asked.

Let’s use the Simcor® bandsaw blade as an example. Since the Simcor blade has teeth that extend beyond the blade, those teeth remove material while cutting, which creates a channel for the rest of the blade to saw through. It also limits blade wander throughout the entirety of the cut.

Blades for Rigid Foams

Choose the right rigid foam saw blades for clean cuts every time.

When you’re working with rigid foams, it’s time to get serious and use a sawing blade, or a blade with a set.

A blade with a set is really just a blade with teeth that extend beyond the blade. Why is this important? We’re glad you asked.

Let’s use the Simcor® bandsaw blade as an example. Since the Simcor blade has teeth that extend beyond the blade, those teeth remove material while cutting, which creates a channel for the rest of the blade to saw through. It also limits blade wander throughout the entirety of the cut.

CNC/Contour and Wire Cutting Blades

Wire blades for foam cutting provide precise cuts for every application.

Are you using contour cutting machinery to cut patterns of all shapes and sizes into foam? We’ve got a blade for that. Actually, we have several.

Simmons manufactures a range of CNC blades with various edge types. Each one is specifically designed to meet the demands of your foam-cutting operations, no matter the application.

Finding the “right” CNC blade depends on the needs of your foam-cutting operations. For example, if your blades are becoming worn down too quickly, we recommend trying Simmons' DuraBand CNC blades. DuraBand CNC blades are made from specialized steel to increase the blades' durability and retain sharpened edges longer, thereby extending blade life.

You can find more detailed information regarding our CNC blades here. Simmons also offers Wire blades in several levels of abrasiveness for contour foam-cutting machinery, which you can learn more about here.

CNC/Contour and Wire Cutting Blades

Wire blades for foam cutting provide precise cuts for every application.

Are you using contour cutting machinery to cut patterns of all shapes and sizes into foam? We’ve got a blade for that. Actually, we have several.

Simmons manufactures a range of CNC blades with various edge types. Each one is specifically designed to meet the demands of your foam-cutting operations, no matter the application.

Finding the “right” CNC blade depends on the needs of your foam-cutting operations. For example, if your blades are becoming worn down too quickly, we recommend trying Simmons' DuraBand CNC blades. DuraBand CNC blades are made from specialized steel to increase the blades' durability and retain sharpened edges longer, thereby extending blade life.

You can find more detailed information regarding our CNC blades here. Simmons also offers Wire blades in several levels of abrasiveness for contour foam-cutting machinery, which you can learn more about here.

Blade Compatibility with Foam Cutting Machinery

We’re proud to be able to say that Simmons’ bandknives, bandsaws, and reciprocating blades can be used in conjunction with almost any foam cutting machine, including CNC machines, vertical and horizontal slitters, carousels, convoluters, peelers and more. Contact us today to see how we can service your foam cutting needs.

Blade Compatibility with Foam

Cutting Machinery

We’re proud to be able to say that Simmons’ bandknives, bandsaws, and reciprocating blades can be used in conjunction with almost any foam cutting machine, including CNC machines, vertical and horizontal slitters, carousels, convoluters, peelers and more. Contact us today to see how we can service your foam cutting needs.

400 Regency Drive, Glendale Heights, IL 60139 | Email: sales@simcut.com | Phone number:+1.630.912.2880

400 Regency Drive, Glendale Heights, IL 60139

Email: sales@simcut.com

Phone number:+1.630.912.2880

©2022 SIMMONS KNIFE & SAW. All rights reserved.

No images may be utilized, reproduced or transmitted in any form or by any means without prior written permission of Simmons Knife & Saw.