V-TOOTH BLADES

As a more aggressive alternative to our Knife and Scallop blades, the V-Tooth bandsaw blade is ideal for cutting through a wide range of foam types. It’s also a great blade to start with if you’re in the foam fabrication industry and aren’t quite sure what you’re looking for. The blade’s teeth work to penetrate material, which provides a faster cut than a standard Knife Edge blade while still creating minimal dust or waste. V-Tooth blades also eliminate the need for a sharpening or grinding system within your cutting machinery.

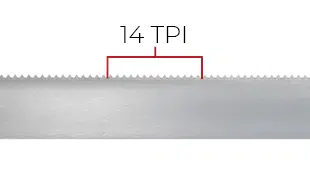

A 14 teeth per inch (TPI) V-Tooth blade is the most common size for foam cutting, but if you’re looking for a more aggressive cut, we recommend a 10 TPI blade. While it may sound counterintuitive, a lower TPI results in a bigger tooth, and a blade with bigger teeth slices more aggressively through dense or rigid foams (and other applications).

For particularly dense or abrasive applications, consider using a Deep V-Tooth blade. This blade has a taller tooth than a standard V-Tooth blade, which helps it stay sharper for longer.

Recommended cutting applications for V-Tooth blades:

- Medium to High-Density Foam

- Packaging Materials

- Plastic Film

- Aluminum Honeycomb

- Filter Media

- Tear-off Tape Dispensers

- Sponges

- Bread & bun slicing

Consistently delivering high-quality blades has been key to Simmons’ success throughout the years. As part of our reliable welds guarantee, if a Simmons blade breaks at the weld, just let us know and we’ll replace that blade for you.

We stand behind our workmanship, and even when we’re not at fault for blade issues, we frequently invest in analyzing the cause of the blade’s failure in order to educate our customers and help them correct the source of the issue in their facility.

Double Edge Single Bevel (VSSB)

Single Edge Single Bevel (VSB)

Double Edge Double Bevel (VDDB)

Single Edge Double Bevel (VDB)

As part of our V-Tooth blade production process, Simmons offers an additional option to harden the cutting edge of the blade in order to extend overall blade life.

*Does not apply to double edge blades.*

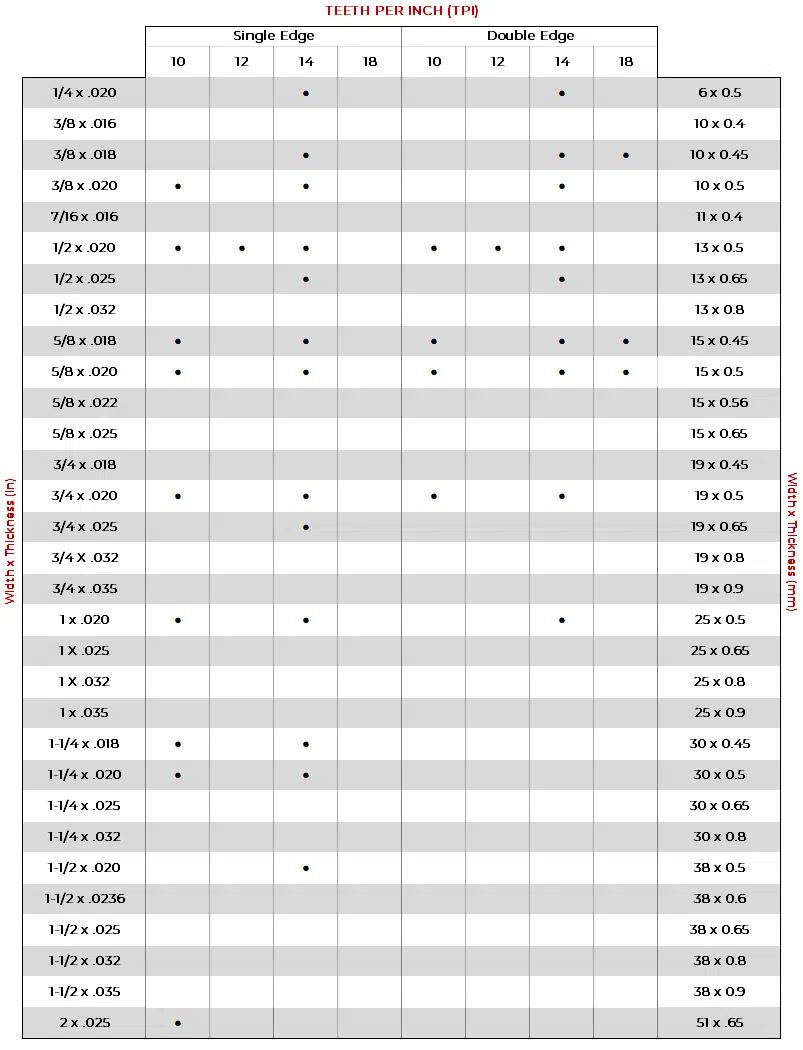

TPI refers to the number of teeth per inch along the edge of the blade. While 10 and 14 TPI are the most common for V-Tooth, we can produce many other tooth configurations upon request. Just drop us a line and we’ll get started.

For 3mm to 4.5mm, please visit our CNC Blades page.