GRINDING WHEELS & ACCESSORIES

Choosing the right grinding wheel is crucial to optimizing blade life. Simmons offers a variety of flat and cupped grinding wheels, all compatible with our bandknife and bandsaw blades.

Conventional vitrified abrasive wheels grind faster and cooler than many other grinding wheels. They also require fewer dressings.

Ceramic wheels typically last longer and grind cooler than conventional wheels. If used properly and frequently, they can also extend the life of a blade.

Able to withstand temperatures above 2,000 C°, Borazon wheels can grind more material at a higher degree of precision than almost any other grinding wheel. Borazon wheels can last up to 10 times longer than conventional grinding wheels, and they’re known to significantly extend blade life when used properly.

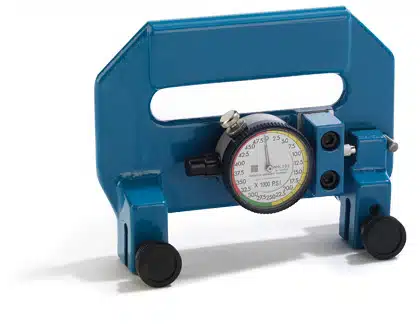

Tension Meters

A tension meter measures blade tension on bandknife and bandsaw machinery. Simmons recommends setting blade tension with a tension meter each time you replace a blade or perform any sort of machine maintenance. Doing so has proven to increase blade life and reduce machine maintenance costs, both of which help reduce overall operating costs.

Contact us today to learn more about Simmons's grinding wheels and other accessories!